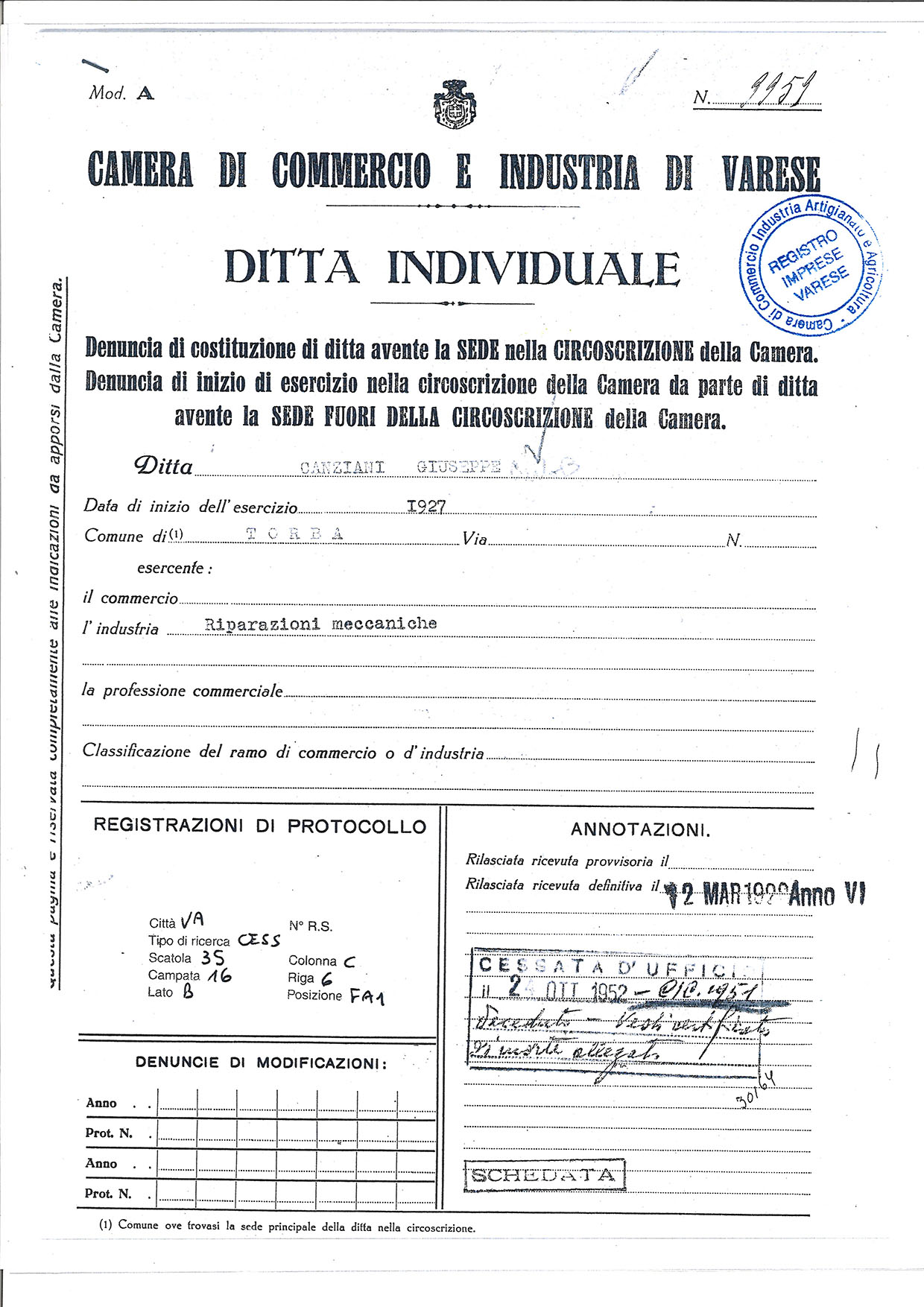

Presma origins date back before World War II. In 1927, when Twins Giannino and Luciano were born, Grandfather Giuseppe established Co. CANZIANI GIUSEPPE CARLO –riparazioni meccaniche. Thanks to the inventiveness of Alberico, the first-born son, the first manual press for thermoplastic was built in 1937, and in this year Presma’s history began.

In August 1937 Alberico, 21 years old, visited the Exhibition in Leipzig (Germany) where he saw items produced in polystyrene (Trolitul). At this time, the Canziani’s family activities included the production of cutting machines, for the manufacture of combs, made of horn, imported from Africa.

In August 1937 Alberico, 21 years old, visited the Exhibition in Leipzig (Germany) where he saw items produced in polystyrene (Trolitul). At this time, the Canziani’s family activities included the production of cutting machines, for the manufacture of combs, made of horn, imported from Africa.

Alberico’s idea was to “form” finished combs at which he succeeded. He designed a system, mounted on a wooden support, composed of a manual piston to inject the material he got from Germany, and of a manual toggle system used for the mould clamping.

With this invention the Canziani brothers started their comb production. The German material turned out to be too breakable, the comb teeth broke too easily.

By chance, Mazzucchelli, an historical group of the Varese area, started the production of Rhodoid, cellulose acetate. It was the first injectable plastic material. From then the production of combs increased considerably and brought to the development of water hydraulic presses.

Italiano

Italiano Русский

Русский