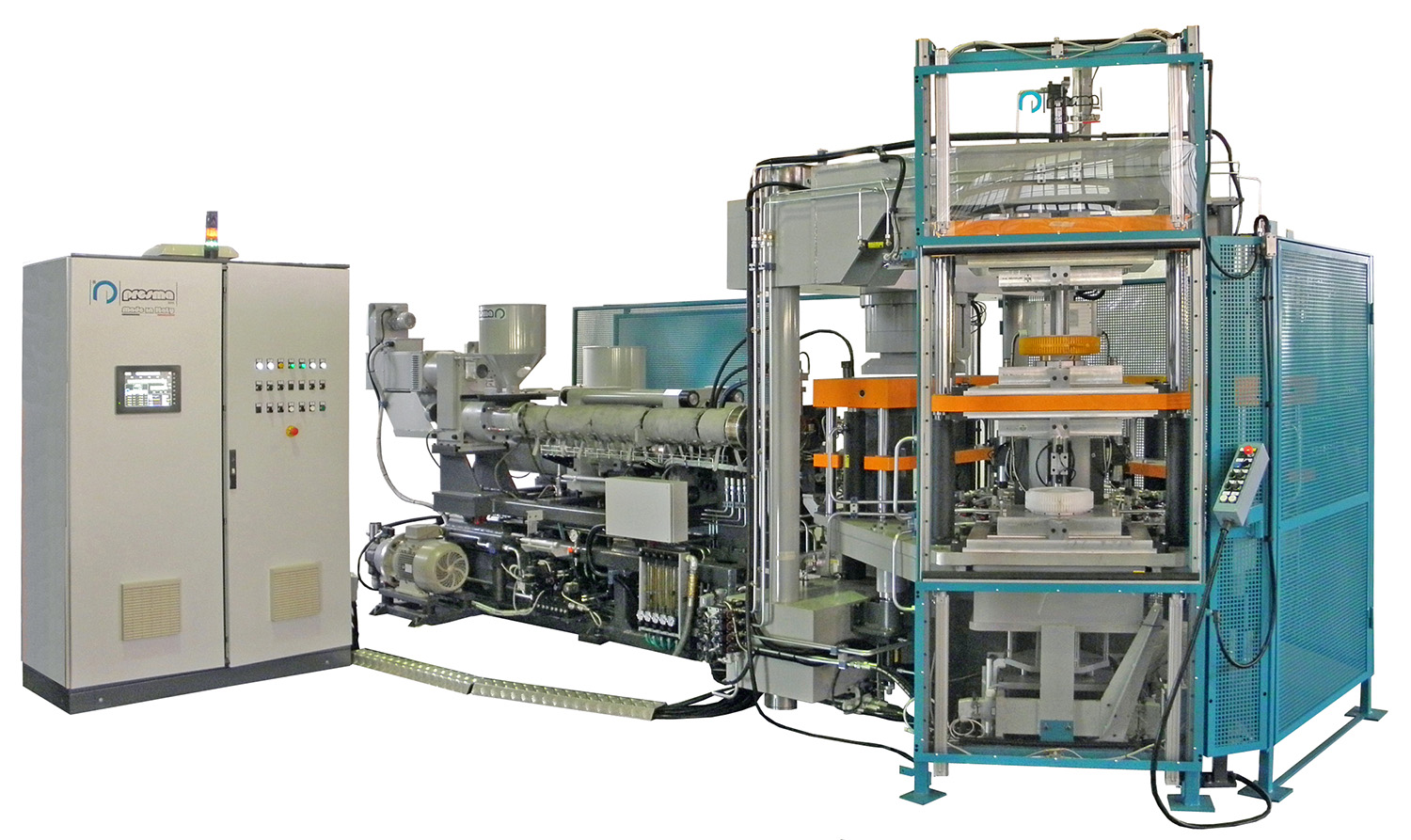

Type of machine: Vertical rotary injection moulding machine

Commodity sector: Wheels, Special rotary machines, Moulding on insert

3 station rotary table injection moulding machine, vertical opening and double overlaid transfer injection unit.

Horizontal injection group with overlaid screw and lever operated nozzle.

Electrical driven plasticizing screw by gearbox with parallel axes and inverter.

Feeding hopper equipped with quick discharge device.

Position linear transducers control both the injection group stroke and injection phase.

Vertical clamping unit with 2 tie-bars; Tool opening and clamping by double hydraulic cylinder.

Hydraulic ejectors both on the lower and on the upper part of the mould holder group, placed on the opening and discharging position.

Short stroke hydraulic cylinder for high pressure during injection process.

Electrical driven carousel rotation equipped by inverter; centering devices to guarantee the correct station positioning

Italiano

Italiano Русский

Русский